- BCM Transtech

- Other products

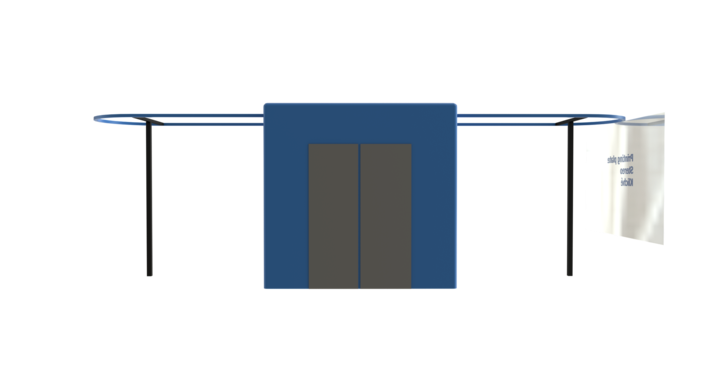

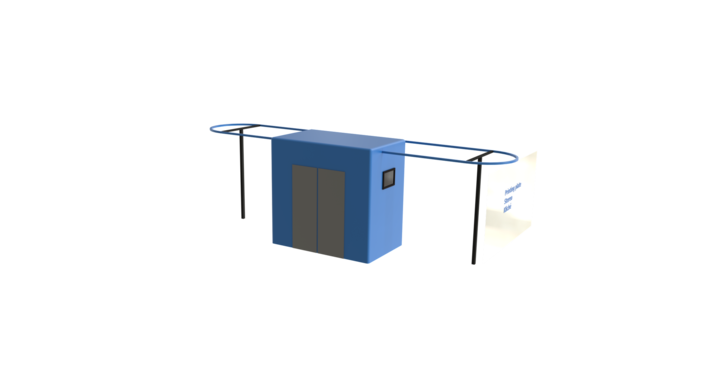

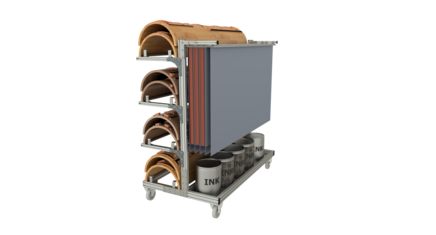

- CleanFlex

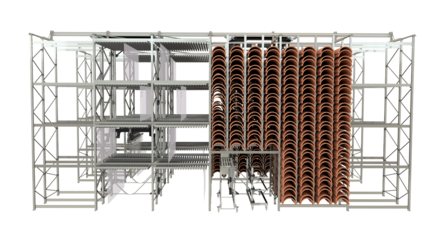

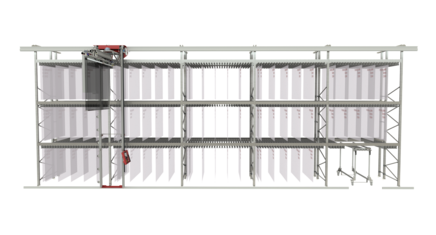

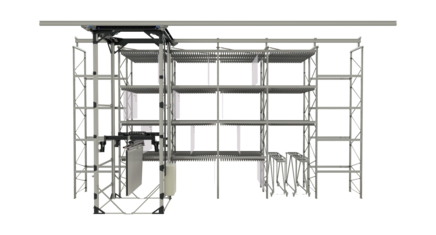

PRINTING PLATE STORAGE

CleanFlex

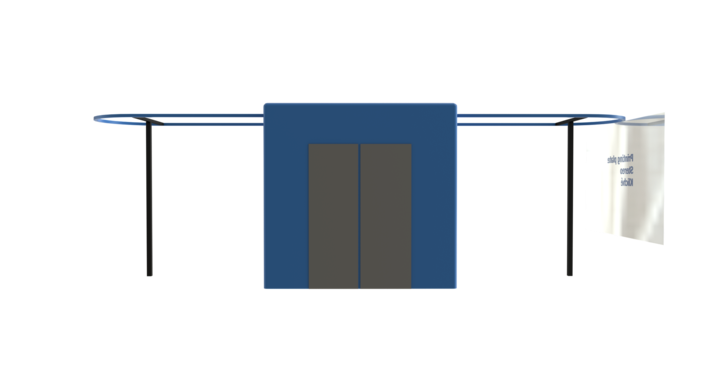

The best print quality is obtained through well-maintained flexo stereos / printing plates. The CLEANFlex is an automatic washing machine for flexo stereos / print plates in both big and small formats. It outperforms manual cleaning because it thoroughly cleans both the flexo stereo’s front and backside by applying an optimal cleaning pressure and rinsing flow through a combination of rotating brushes, pressurized water nozzles, soap and defoamer. At the end of the process, it blow-dries the flexo stereos so they can be stored right away. The CLEANFlex is a must-have if you want to take optimal care of your flexo stereos as the cleaning process yields the best results every time.

Product description

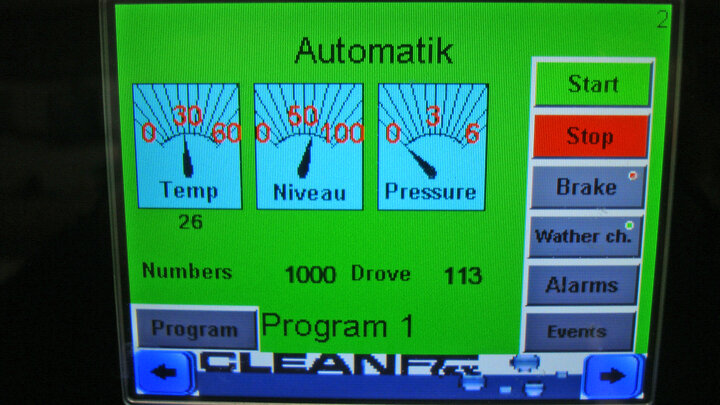

Efficient, durable, and reliable operation: The stereos are cleaned and dried automatically so they can be stored right away. Absorbing soft backing might not always be completely dry, thus depending on the composition of the print plates or stereos, the customer’s need to pay attention to this.

Maintain high print quality in the long run: Thorough cleaning of the flexo stereos / printing plates front and backside at the same time.

Easy, simple, and user-friendly to operate: Easy to setup and teach new operators. Attach the flexo stereos to the profiles and choose the preferred program.

Environmentally friendly: Minimal consumption of water and energy, while water, soap and anti-foam are filtered and reused several times.

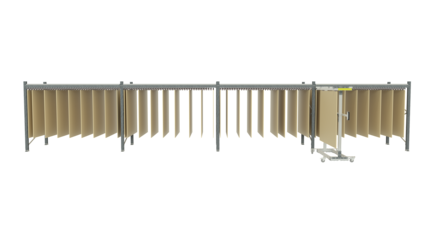

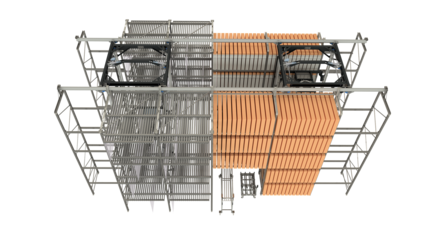

The CLEANFlex can handle printing plates / flexo stereos up to 1.8 m X 3 m. The average speed of the CLEANFlex is app. 2 m./min. at a stereo height of 1.8 m = 216 m2 / hour. Cleaning speed does depend on type and design of the printing plates and also how “dirty” the plates/stereos are. If the stereos or printing plates are very dirty or with dried ink, just leave the plate on the conveyor and run it through the machine again for extra cleaning.

Sustainability: Compared to manual cleaning of print plates, the CLEANFlex is a more sustainable solution, since it recycles the wash water, soap and defoamer until the operator decides to change the wash water, when it no longer meets the desired cleaning quality. By pressing the water change button, the wash water is pumped out and replaced with fresh water, and the machine automatically adds the preset amounts of soap and defoamer, to ensure low consumption of water, soap and defoamer.

The CLEANFlex washing machine for print plates and stereos is able to serve multiple converting machines, Masterflex machines, etc. It runs at a constant speed and the operator only need to hang the stereos onto the machine and take them down again once they have completed the entire circle and washing routine. In case a stereo is very dirty, heavy colored or the ink has been sitting on the stereo for a long time, the CLEANFlex washing routine can simply be continued until the stereo / print plate is clean again.

Intem number: 1004075

Machine incl. conveyor:

- Length: 8640 mm

- Width: 1900 mm

- Height: 2700 mm