CASE STEMPHER - FLEXIBLE PACKAGING

Semi-automatic sleeve

storage solution

"

“Flexible Packaging industry” – bcm transtech have delivered several storage systems to the flexible packaging industry.

Today two different concepts are available at bcm transtech a/s in Denmark to make a great storage solution for sleeves.

This case shows one of these two options. Within each option we have large flexibility and customization opportunities.

The situation:

Customers in the flexible packaging industry are handling large and heave rolls or sleeves, as they are also called. As in the corrugated industry there is a need for correct handling, storing and space saving initiatives in these factories. Based upon our existing rack systems and modified crane solutions from the corrugated industry, bcm transtech is able to supply great solutions in this industry too. Often there is also a demand for handling the sleeves between the storage itself and the printing machines. Sleeves must be prepared with the printing foil and they must be transported carefully from one area to the other, as well as in and out of the printing machines. All these storing and handling processes are vital and bcm would be happy to assist with solutions for this. This case shows some examples of these opportunities our customers have with the bcm solutions.

The situation

Customers in the flexible packaging industry are handling large and heave rolls or sleeves, as they are also called. As in the corrugated industry there is a need for correct handling, storing and space saving initiatives in these factories. Based upon our existing rack systems and modified crane solutions from the corrugated industry, bcm transtech is able to supply great solutions in this industry too.

Often there is also a demand for handling the sleeves between the storage itself and the printing machines. Sleeves must be prepared with the printing foil and they must be transported carefully from one area to the other, as well as in and out of the printing machines. All these storing and handling processes are vital and bcm would be happy to assist with solutions for this.

This case shows some examples of these opportunities our customers have with the bcm solutions.

The solution

This particular solution is divided into three parts, all of them designed and delivered by bcm transtech.

- The rack itself where the sleeves are kept safe and well organized in the bcm cassettes. Each cassettes contains well specified sleeves and the production planning department always know where to find the relevant sleeve. Each cassettes contain several sleeves, which can have different sizes.

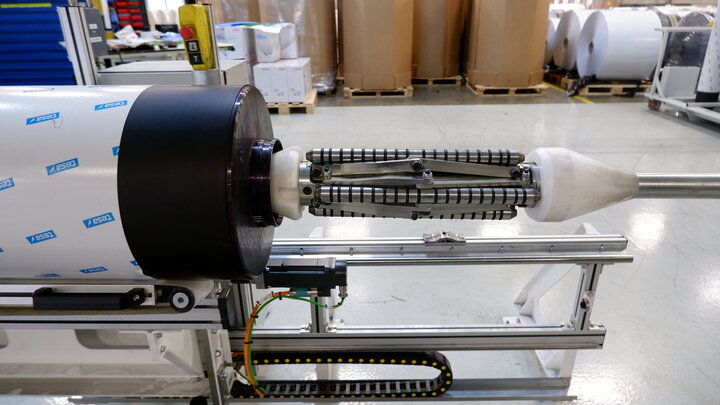

- The bcm Sleeve Mobilator takes the sleeves from the cassettes by means of an expansion lifting unit and the end of the crane arm. The same crane arm with the expansion lifting unit is also used when returning the sleeves to the cassettes and it is also used when the sleeves are delivered to the bcm Mounter Lifting Table.

- The bcm Mounter Lifting Table is where the sleeves are placed by the bcm Sleeve Mobilator. From the Mounter Lifting Table the sleeves are inserted to the printing foil machine and the print is attached to the sleeve before inserted into the printing machines.

Operation of bcm SmartStorage P1, F-type

The storage crane is semi-automatic (SmartStorage), which means that software supports the operator in finding the right level and location to work in during lifting and moving. Thus, the bcm SmartStorage technology helps the operator to ensure correct and safe operation both for the operator and for the sleeves.

The touch panels are easy to understand with clear icons and text principles that everybody can learn and use with just a few hours of training. Also, it doesn’t require any specific background or education to operate the bcm SmartStorage cranes. On the bcm Sleeve Mobilator, with the expansion lifting unit, the operation is also aided with smart functions, which give the operator great support when collecting and returning sleeves to and from the cassettes. Also, when working at the bcm Mounting Table the system supports the operator very well.

Alternative sleeve storage solutions

This particular solution is divided into three parts, all of them designed and delivered by bcm transtech.

- The rack itself where the sleeves are kept safe and well organized in the bcm cassettes. Each cassettes contains well specified sleeves and the production planning department always know where to find the relevant sleeve. Each cassettes contain several sleeves, which can have different sizes.

- The bcm Sleeve Mobilator takes the sleeves from the cassettes by means of an expansion lifting unit and the end of the crane arm. The same crane arm with the expansion lifting unit is also used when returning the sleeves to the cassettes and it is also used when the sleeves are delivered to the bcm Mounter Lifting Table.

- The bcm Mounter Lifting Table is where the sleeves are placed by the bcm Sleeve Mobilator. From the Mounter Lifting Table the sleeves are inserted to the printing foil machine and the print is attached to the sleeve before inserted into the printing machines.