- BCM Transtech

- Corrugated Storage Solutions

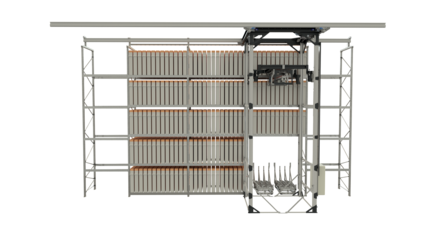

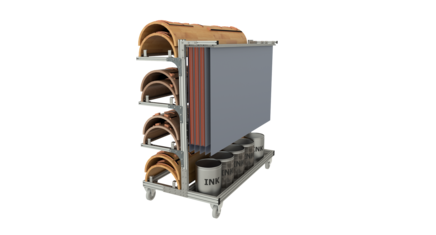

- SmartStorage FRP2, T-type

FLAT BED DIE/ ROTARY DIE /PRINTING PLATE STORAGE

SmartStorage FRP2, T-type

The bcm SmartStorage is an upgraded and smarter version of the bcm PrimeStorage with a touchscreen PC, remote access devices and several software features, and with more software options available. All bcm SmartStorage solutions have software to aid the operator with automatic location identification and semi-automatic functions to ensure correct pick-and-place of all dies and printing plates.

The bcm SmartStorage is still a manually moved craned. However, the operator gets assistance from the software to help in not making mistakes in either storing or operation of the equipment.

Software options such as “Report Module”, “Industry 4.0” and more make the bcm SmartStorage attractive to many customers. For customers who want a smart storage system, where full-automatic is not required, the bcm SmartStorage is a good choice.

Our customers receive an effective storage system which is well-organized and dies and printing plates can be combined in almost endless combinations.

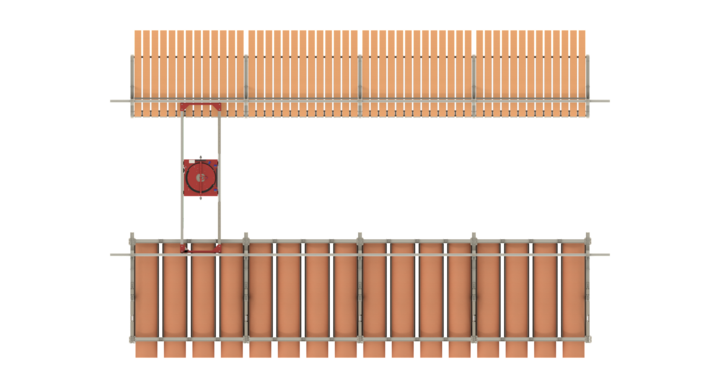

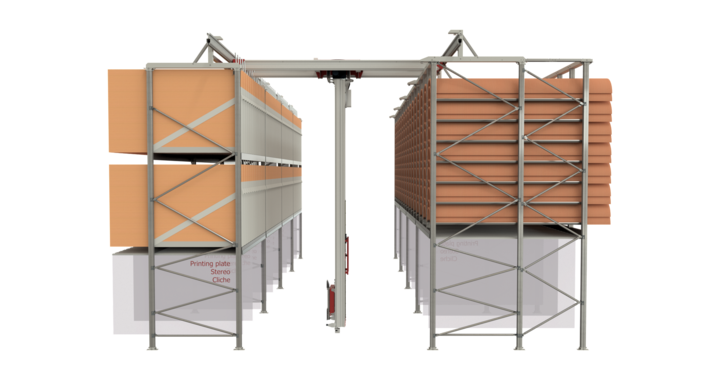

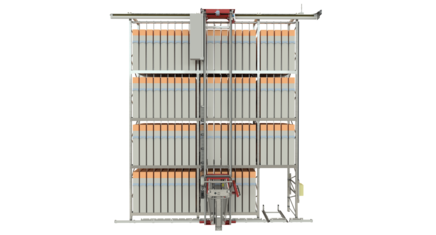

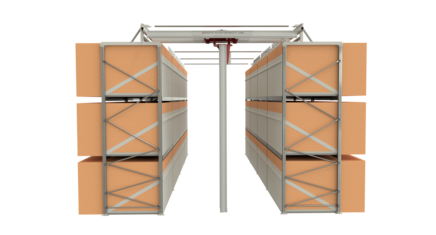

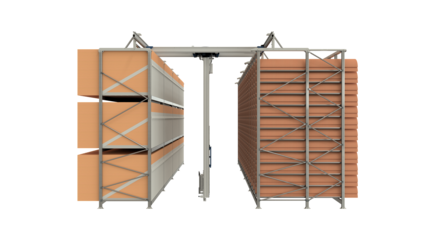

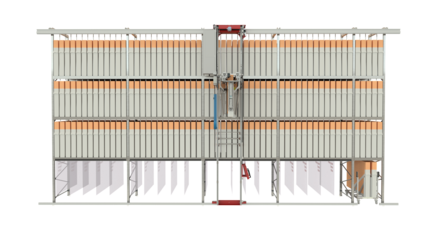

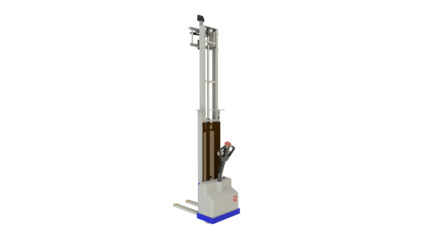

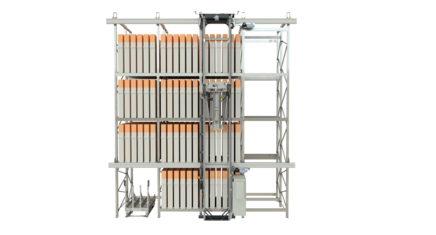

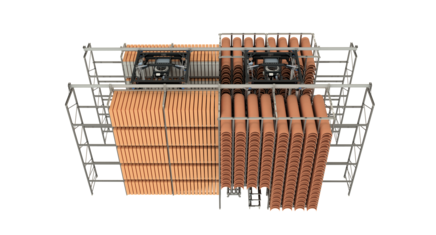

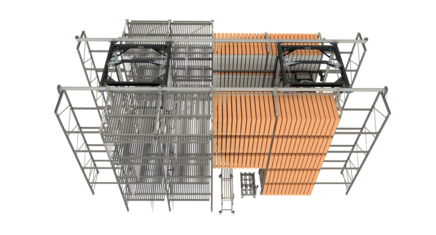

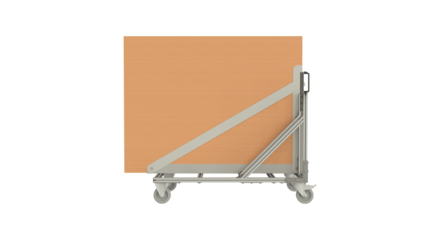

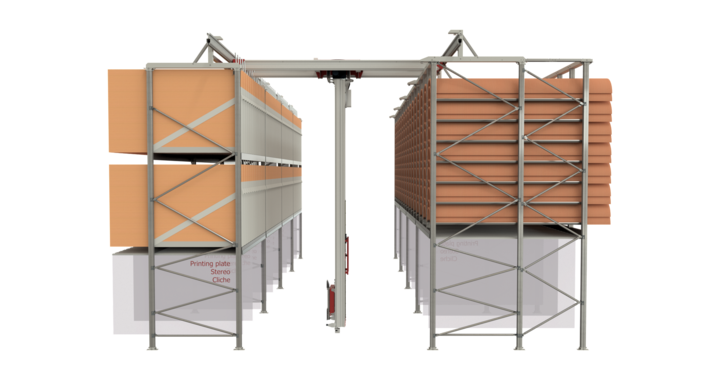

Product descriptionThis semi-automatic double rack storage for flatbed dies, rotary dies and printing plates, with an overhead-mounted crane, has a high capacity but with a small footprint in the factory, especially if the storage system can be built high. By having two racks instead of one rack, our customers are doubling the capacity but at the same time only increasing the footprint by app. 50%. When the storage is not in use, the operator can “park” the crane higher up in the storage to give space for free passage between the two racks in the storage. The storage structure is built mainly from galvanized steel. The hoist is motor driven with steel-wire and ensures precise positioning and smooth operation, a requirement for the software programs in bcm SmartStorage solutions. The crane and the crane rails are a combination of aluminum, galvanized steel and powder-coated steel. All bcm SmartStorages have as standard: Remote access devices for on-line support, PC with touchscreen, clear icons for easy operation, database, camera on crane and software-controlled lifting and lowering to avoid any collisions inside the storage. Also incorporated is the needed software for the semi-automatic processes, and it is prepared for multiple options such as “Industry 4.0”, “Report Module” and “ID Tags on all parts”. When operating the bcm SmartStorage cranes the operator first enters the tools required. Each tool (die or printing plate) has their own unique position in the storage which is entered into the PC. By entering the tool number on the touch screen the crane knows exactly where to drive and how to position itself correctly. Thus, when the operator moves the crane manually, he will have the software to tell him when he is in the right position. Only then he can move into the storage and take out the tools needed. Moving in and out and lifting and lowering is also controlled by the crane software. In this way operator mistakes are eliminated, time is optimized, and the operator cannot damage either storage or tools because the crane’s software is controlling all these movements. The rotary dies can be organized as either single dies or as double dies in the bcm storages. This must be clarified in the specification phase. The customer gains app. 20-25% extra space with double dies compared to single dies. However, the biggest benefit of double dies is that the operator only needs to pick up one time for a complete set of two half shell dies, reducing manpower on the entire operation. This bcm SmartStorage solution contains both flatbed dies, rotary dies and printing plates. The rotary dies are collected by adding an adaptor to the cassette gripper. This adapter can easily be lifted on and off the cassette gripper and handled by one single operator. The customer can also choose to have a fixed position in the storage as garage for this rotary die gripper. The printing plates are in the lowest level of the storage and handled manually without use of the semi-automatic crane The trolleys for the storage are on wheels and designed to contain 3 cassettes as standard, 3 double rotary dies or 4 single rotary dies. A separate trolley for printing plates is also available or in printing plate trolley in combination with rotary dies. The trolleys can be placed in a garage or anywhere in the aisles of the storage area as this crane can rotate 360 degrees. Each cassette contains everything needed for one full set of dies for production (cutting die, stripping die, guillotine board and printing drawing). The trolleys are easy to handle and can be pushed by just one person. When the operator enters the storage area to pick up the cassettes with the dies, the operator just brings the trolley into the aisle and can thereby reduce the time of moving the crane significantly. |

Item number: 5031344

- Tools 1: Flat bed dies in cassettes

- Tools 2: Rotary dies

- Tools 3: Printing plates

- Color: Traffic Red (RAL 3020)

- Levels: 2-7*

- Height: 3-10 meters

- No. of racks: Two racks

- Software options: Yes

- Automation level: Semi-automatic

*Dependent on the printing plate and die size