- BCM Transtech

- Corrugated Storage Solutions

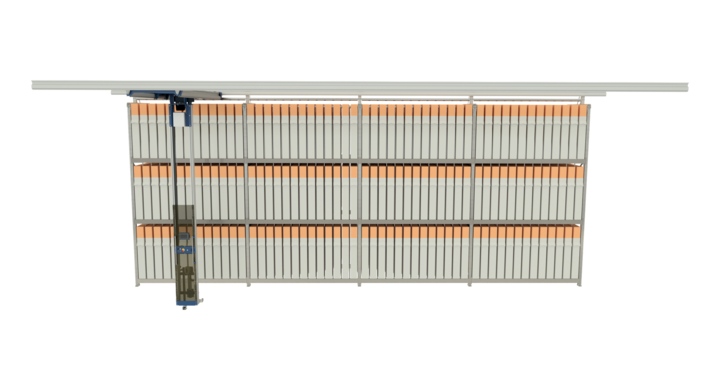

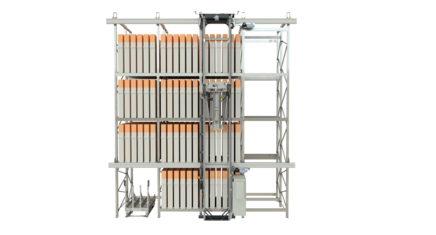

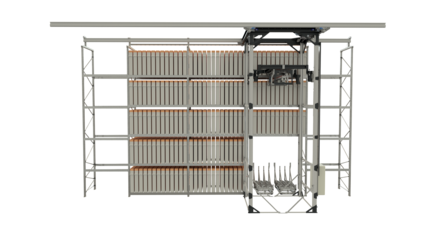

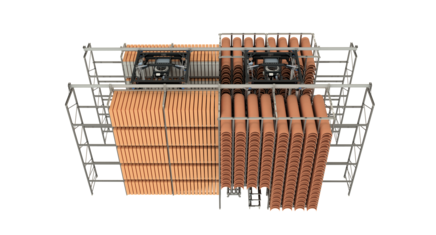

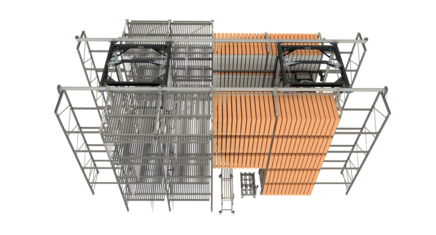

- PrimeStorage F1, T-type

FLAT BED DIE STORAGE

PrimeStorage F1, T-type

The bcm PrimeStorage is the most sold storage system in the corrugated industry and its popularity is easy to understand. Our customers receive an effective and well-organized storage system, where dies and printing plates can be sorted in almost endless combinations. Furthermore, the bcm PrimeStorage is easy to operate and its value for money is extremely high.

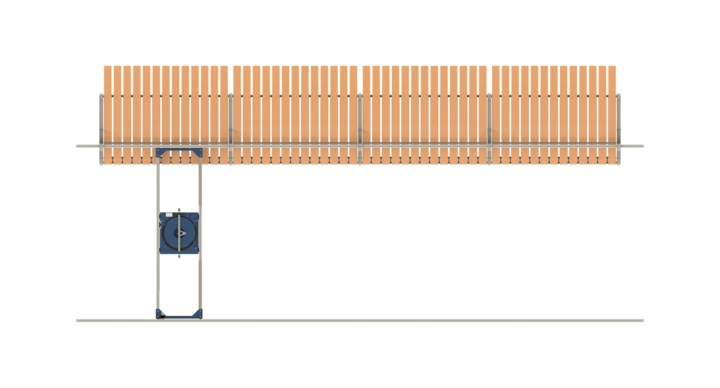

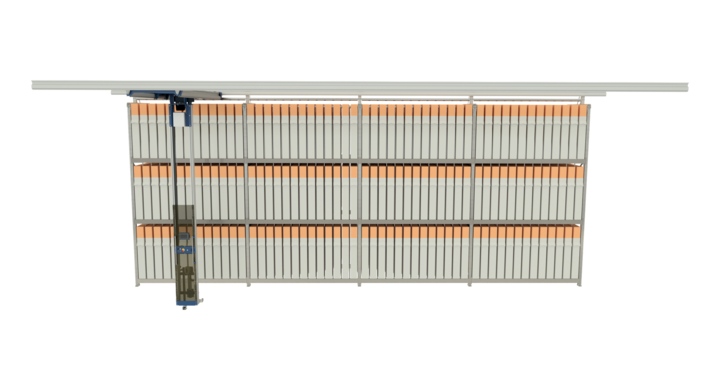

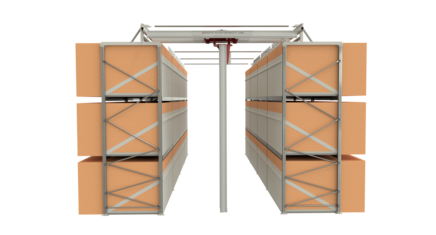

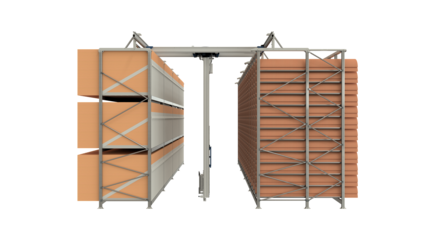

With an overhead-mounted manually operated crane, this manual single rack storage for flatbed dies is useful if lacking the required space for two racks. The single rack system is especially valuable if you have a small floor area or a free wall area but traffic in the aisle or corridor. After use, the operator can “park” the crane higher up in the storage to permit free passage in front of it.

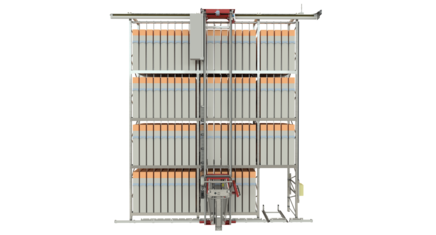

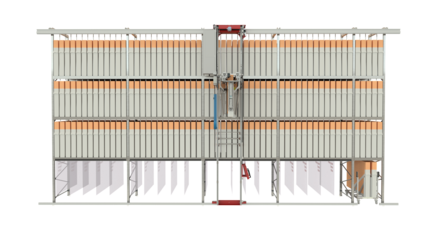

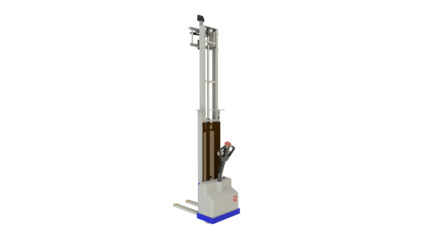

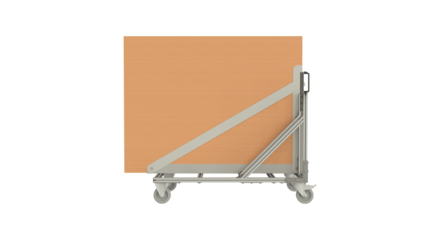

Product descriptionThe storage structure is built mainly from galvanized steel. The crane and the crane rails are a combination of aluminum, galvanized steel and powder-coated steel. The monitor has two cameras —an upper and a lower — to support the operator while operating the crane. The operator can move the crane manually and, at the same time, drive the sleigh with the cassette gripper up and down in a vertical direction. This is time-saving, making operation of the crane efficient, especially with high storage. The bcm PrimeStorage F1, T-type can combine in a storage solution both rotary dies and printing plates, all in the same storage and with only one crane for both types of dies. The printing plates are placed in the lowest level of the storage and handled manually – without using the crane. The rotary dies are handled with an attachable arm which is connected to the flatbed die handling device. The trolleys for the storage are on wheels and designed to contain three (3) cassettes as standard. Each cassette contains all plates needed for one complete set of production dies (cutting die, stripping die, guillotine board and printing drawing). The trolleys are easy to handle and push by one person. When entering the storage area to pick up the cassettes with dies, the operator can just bring the trolley along, thereby reducing the time of moving the crane significantly. This single rack PrimeStorage solution for flatbed dies is not available as a front-mounted crane in the bcm PrimeStorage program. If customers want a front-mounted crane for cassettes, they need to choose either the bcm SmartStorage (semi-automatic) or the full-automatic bcm AutoStorage. A simpler alternative would be the bcm PrimeLift that collects the cassettes with a lift that is not connected to the storage system. If choosing the bcm PrimeLift, the maximum lift height is only three (3) levels of dies/cassettes. Compared to the single rack F-type storage, one particular advantage of this T-type storage is that the tools can be delivered into the trolleys in more locations, as this T-type crane can rotate 360 degrees whereas the F-type cranes cannot rotate. When the operator is working in the storage, nobody else should be in the aisle due to safety reasons. |

Item number: 5031241

- Tools: Flat bed dies in cassettes

- Color: Traffic blue (RAL 5017)

- Levels: 2-7

- Height: 3-10 meters

- No. of racks: One single rack only

- Software options: None

- Automation level: Manual

|

.png)