- BCM Transtech

- About bcm

- How we operate

How we operate

How we operate

It all starts at our customers. No matter if our customers have small or large projects, bcm transtech can solve it all. First contact is always through our agents – their contact information can be found under “Contacts/Sales Agents”. Our agents are able to discuss with you the solution needed and continue the dialogue with bcm. If there is no sales agent in your territory you can contact bcm transtech directly either on: bcm@bcm.dk or quotation@bcm.dk. Naturally, you are always welcome to call us by phone as per the contact information on our website.

bcm nominated to SMV digital in 2021

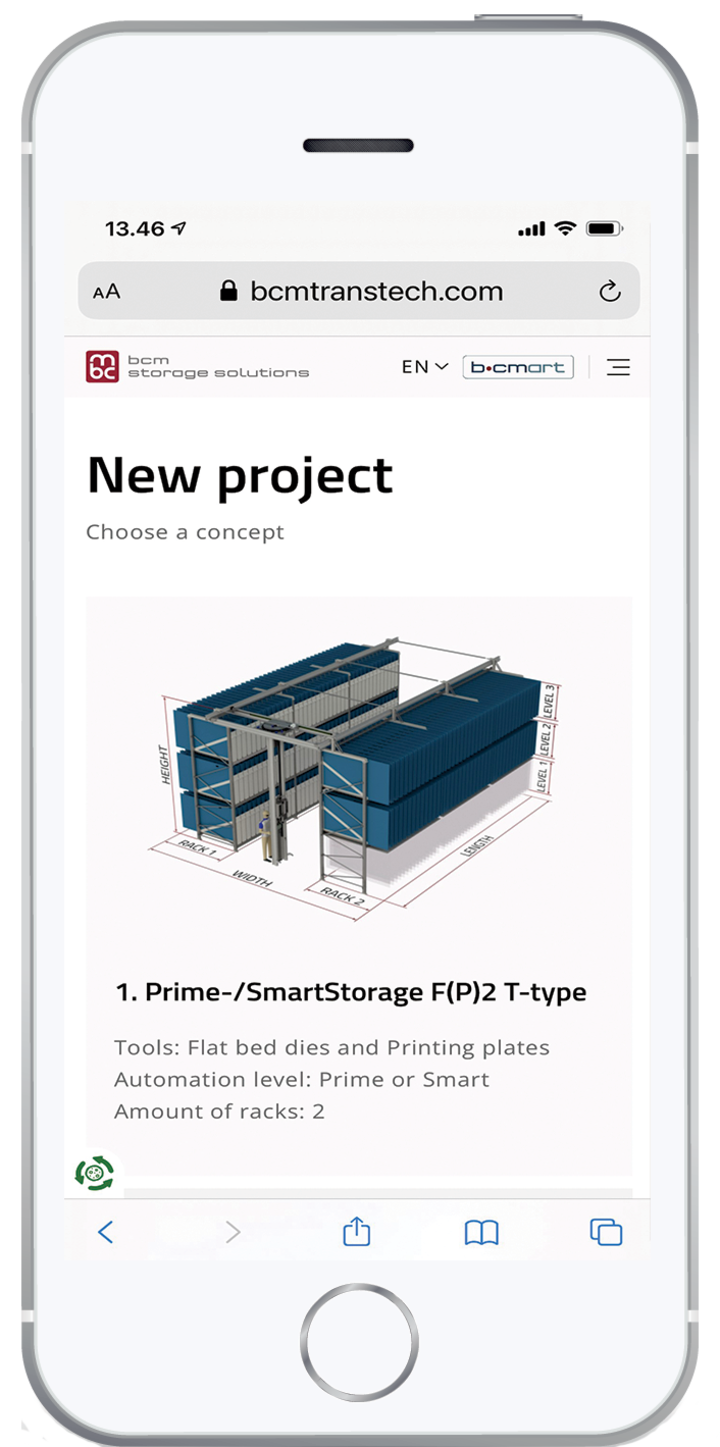

bcmart is our new tool

In 2021 bcm launched also a new sales tool for the use of bcm’s agents and bcm’s own employee only. This sales tool is called “bcmart” (read: be smart). It allows us to type in few parameters for different bcm transtech concepts and storage types and within minutes a 2D DWG and a 3D pdf is returned displaying clearly the layout of the storage solutions just made with the customer.

The bcmart tool from bcm transtech is not only unique in its technology, it is also very easy to use. As it is available both on smartphones, tablets and on pc, bcm’s sales team can even make the layouts and configuration of the storage solutions with the customers directly in the production area. Using bcmart is a process of designing your own storage solution with a representative sales person from bcm. Once the customer designs their first storage solution it is easy to change and correct with numbers, sizes etc.

We are looking forward to hearing from you and assist you in any way we can. click here to contact us

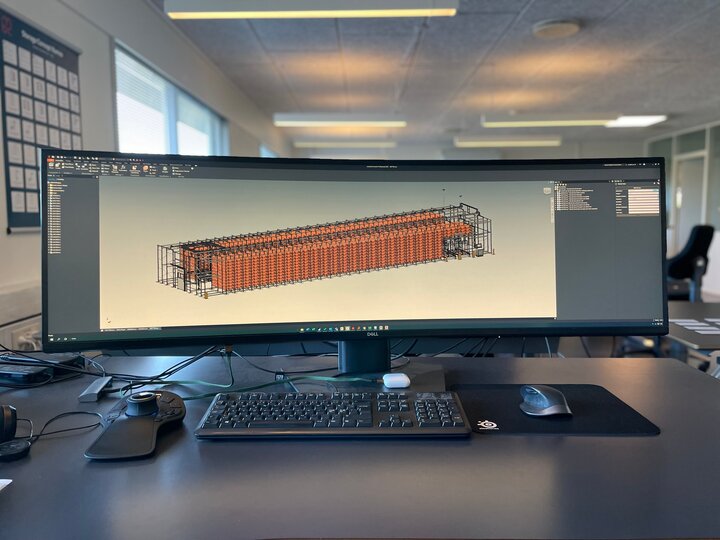

Design process (after order):

The storing of sleeves or rolls has shown to be interesting for bcm and brought new type of customers to the company. Today bcm has developed two different kind of storage solution concepts for this industry and our intentions are to investigate further options in order to develop this market. The handling of sleeves and rolls are also quite particular and often require additional handling equipment and tools. Some of which we have also developed at bcm. But first of all, we are happy to realize that our cranes and storage rack components can also be used in this industry, making it easier for bcm to develop solutions in this industry.

Production process

At bcm we have special systems selected from special suppliers that are being incorporated in our storage solutions. This being both rack system, electronics, steel, and aluminium etc. All of them have proved themselves in the market and are strong, reliable suppliers giving only good quality and value for money.

In our production we also have several own produced items. Most of these are produced on one of our robot cells or cut and bended on our new and modern technology equipment. We have our own smith workshop and electrical workshop too and as such we are able to produce many items ourselves. This gives us full control of the processes and products leaving our factory and ensures quality and capacity needed.

Shipping and installation

A team of dedicated colleagues are ensuring a correct packaging and often one order are multiple trucks loaded and shipped. In Europe we delivery DAP in trucks as standard and overseas we deliver in containers.

At bcm transtech we have a dedicated, well educated and experienced team of craftsmen performing the installation of our equipment and training of our customers. Sometimes, our customers are offered to aid us during installation to save costs. For this we require that such helpers are well educated craftsmen too and that they speak English. Also, they must be available during full working hours during the installation, which is often +10 hours a day.

Customer is always to supply necessary equipment for unloading trucks and containers like: Telehandler and fork lift and during installation bcm need scissor lifts, power and lots of space around the installation for laying out the large pieces of equipment of racking etc.

Since more than 25 years doing installations of rack materials and logistic solutions for storages in the corrugated industry, in the folding carton industry and the flexible packaging industry among others, we are proud to say that we have never had any personal accidents or injuries. Thus, working safe is key to us, which we achieve through skilled craftmanship and good education, correct use of tools etc.