- BCM Transtech

- Other products

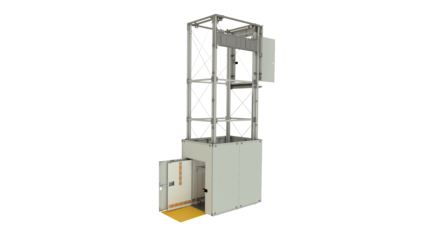

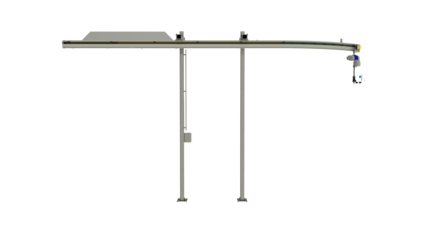

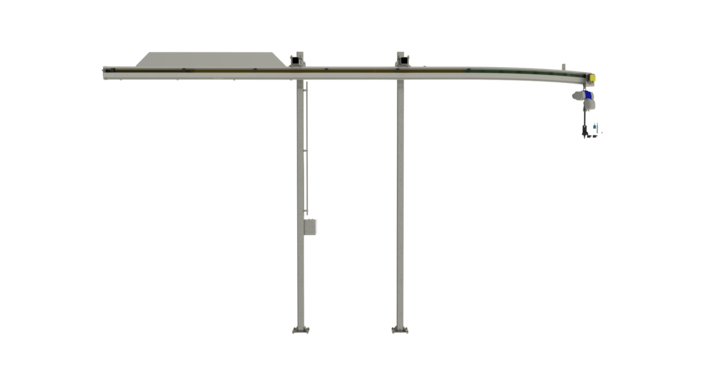

- Mobilator Curved

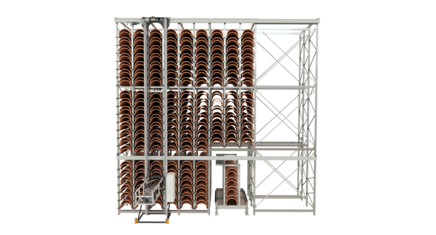

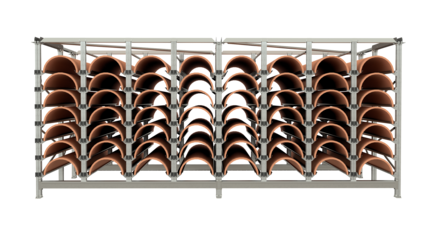

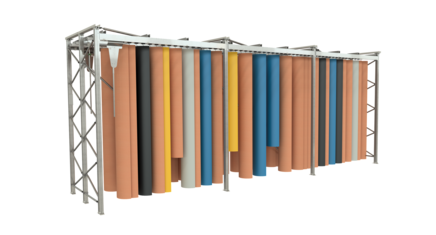

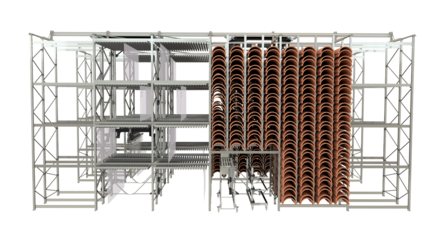

FLAT BED DIE STORAGE

Mobilator curved (for Göpfert Evolution HBL)

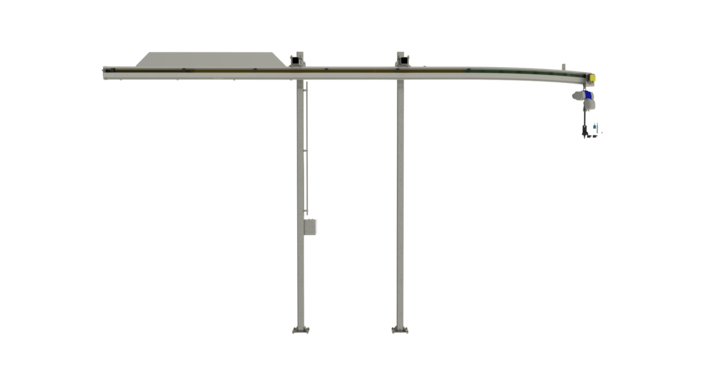

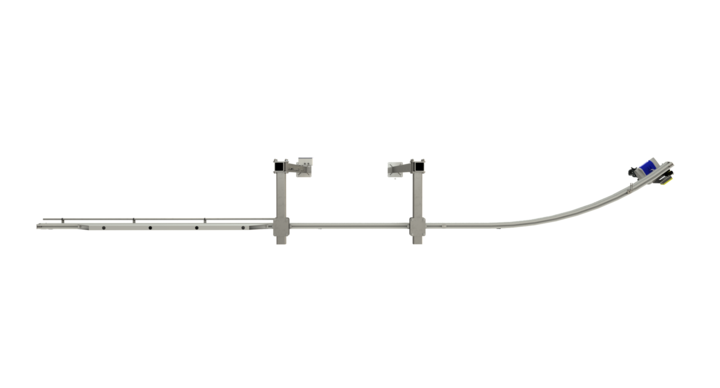

bcm transtech has developed a special curved Mobilator which is able to bring the rotary dies all the way into the cylinder of the rotary die cutter. The crane rail is curved in order for both to fit into the access hole of the rotary die cutter, e.g., the Göpfert Evolution HBL. Please note that the customer must make some modifications on the machine to give sufficient access into the machine, or the customer can buy an option for the bcm Mobilator when ordering the Göpfert Evolution HBL machine at Göpfert.

The crane rail is top mounted, thus a roof structure is needed to setup the bcm curved Mobilator in front the of machine. Please reach out to bcm transtech or one of our agents to learn more about the options of installing a curved Mobilator at your factory.

Product description

Item number: 5031866

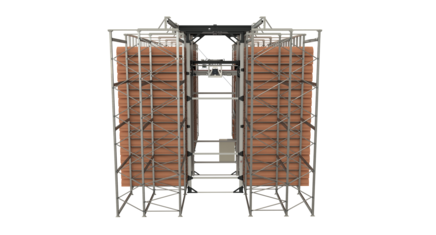

A chain hoist on the Mobilator is used for lowering and raising the connection point to the rotary dies. These connection points must be either drilled into the dies when the customer order the dies by the die manufacturer, or the customer can do this themselves.

The operator can pick up the rotary dies both in horizontal and vertical position. In any case, when the die is being inserted into the rotary die cutter machine, e.g., the Göpfert Evolution HBL, the rotary die needs to be turned into correct position. The fixing point of the Mobilator is on the top part of the die. Once fixed to the rotary die, the mechanism has a small tilting device to enable the operator to turn the die 90 degrees. In this way when the die is going in and out of the rotary die cutter, it is as narrow as possible.

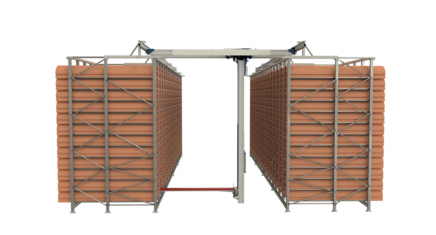

The big advantage of the bcm Mobilator is the ergonomic aspect by using the bcm Mobilator instead of performing heavy lifts manually. No more needs for heavy lifting, and it can be done by only one operator. The entire process to fix a die to the bcm Mobilator, turn it, raise it and drive it in and connect it to the cylinder only takes a few minutes. All operators can easily learn to do this correctly.

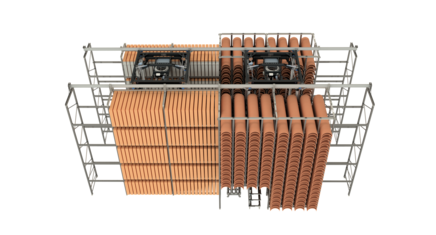

Often customers have their rotary dies standing or hanging very close to the rotary die cutters. In most cases bcm is able to position the Mobilator between the rotary die storage and the rotary die cutter, therefore enabling the operator to pick up the dies directly from the storage and put it into the machine without any kind of heavy lifting or manual handling. This is an advantage for the operator and thus the customer due to working ergonomics and time consumption.

Power supply: 230V 10Amp